Compressed Air Dryers For Blast Pots & Nozzles

Moisture in compressed air negatively affects both the productivity and workmanship of abrasive blasting contractors. The harmful effects of wet air include the clumping or clogging of abrasive grit, inconsistent and/or excessive flow of abrasive, corrosion of ferrous abrasives, and damage to blast machine valves and controls. When abrasive media in a large blast pot becomes damp, the abrasive media often requires total removal from the pot and replacement. This is both time consuming and expensive. Wet abrasive also increases wear on the blast nozzle orifice, leading to higher consumable costs.

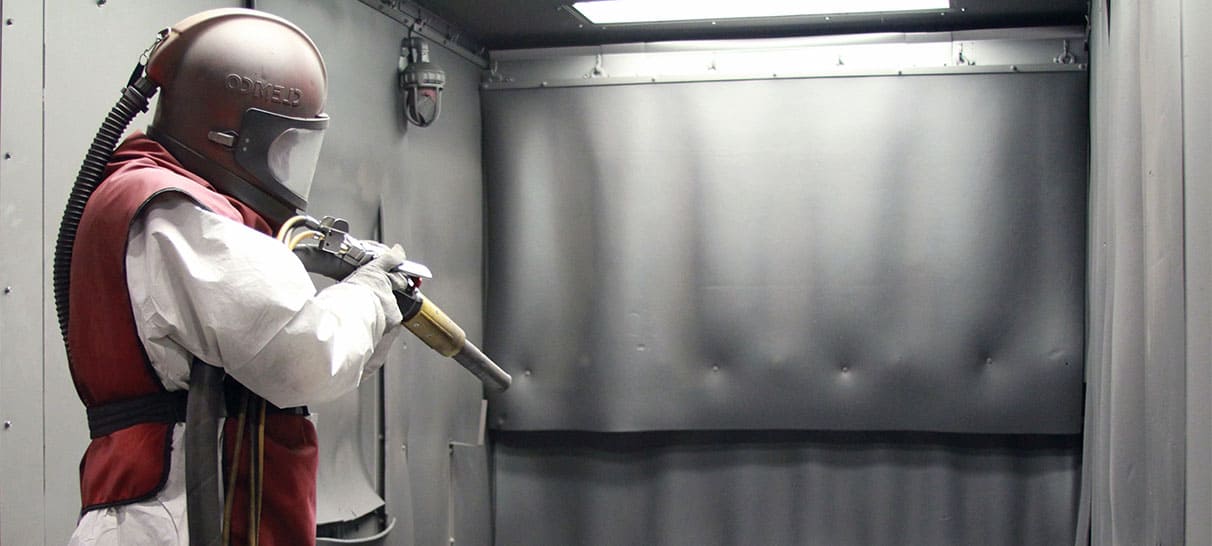

The Blast Pak cools, dries, and filters compressed air in one complete package that’s uniquely designed to eliminate compressed air moisture problems for mobile abrasive blasting contractors. Job sites in this industry are temporary; so the Blast Pak is mobile and portable. Job locations usually have limited access to utilities; so the Blast Pak requires no electrical power.