Rental Air Compressors for Pipeline Dew Point Drying

When a new pipeline is constructed it needs to be hydrostatically pressured tested – hydro testing for short – to ensure there are no leaks in weld seams. This involves pressurizing a segment of the new pipeline with water. After successful hydro testing, the pipeline needs to be “de-watered”. This procedure involves pushing and blowing liquid water from the pipeline. Finally humidity – water present in the vapor state – needs to be removed from the pipeline. In the pipeline construction and service industry, this process is often called dew point drying. It requires atmospheric air to be compressed, cooled, filtered, and dried. The high purity compressed air then flows through the pipeline absorbing humidity. Dew point drying prevents premature corrosion of the pipeline and contamination of the product following commissioning.

Pipeline construction contractors usually do not own their own compressed air dryers for pipeline dew point drying. Since the dryer is for temporary service, it most often make better financial sense for the contractor to rent air drying equipment.

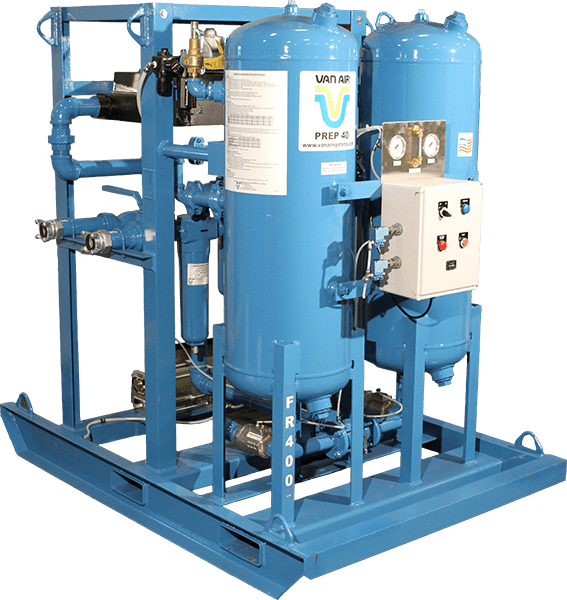

Prep40 Series dryers are designed for rental fleets that support pipeline construction contractors.