Desiccants Search Results for: “”

Brown, gray or off-white activated alumina desiccant beads, does your regenerative dryer desiccant look like this?

Does your regenerative dryer desiccant look like this? Your company may rely on a regenerative desiccant dryer to keep their compressed air in the best-operating conditions for production. Most industrial users of compressed air are familiar with regenerative desiccant air dryers. These dryers are really the only choice when ultra-dry compressed…

Are Deliquescent Dryers Difficult to Maintain? See how easy it is to fill a Desiccant Dryer.

We hear many different comments about our Deliquescent Dryers. One of the foremost common misconceptions we hear about our dryers is that they are challenging to Maintain. This is one misconception we want to squash right here and now. Deliquescent dryers require the least amount of maintenance out of any…

Choosing Replacement Desiccant: Pitfalls to Avoid

Desiccant doesn’t last forever, regardless of the type of compressed air dryer that you have. All desiccant needs to be replaced or replenished eventually. However, a few things have to be pinned down before deciding what material is most appropriate for the dryer. What Type of Dryer is it? Most…

What is Natural Gas Dehydration? Different types of Natural Gas Dryers.

*written by an independant 3rd party* Natural gas dehydration can play a crucial role in the proper operation of your gas processing application. Whether it is an onshore or off shore gas processing facility, pipeline compressor or LNG producing system, adequate dehydration of your process gas can save a substantial…

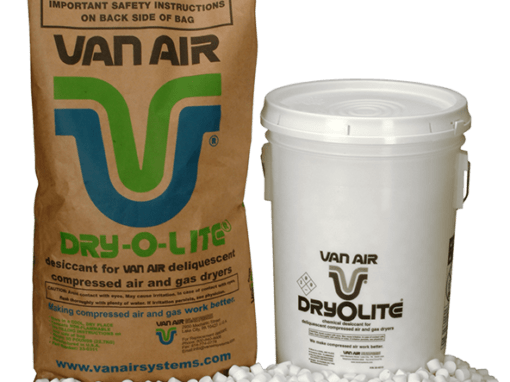

Important Desiccant Maintenance – Replacing Deliquescent Desiccant in your Compressed Air & Natural Gas Dryers

Have you replaced your Dry-O-Lite Deliquescent Desiccant within the last 6 months? If the answer is no, you should replace the Dry-O-Lite Desiccant in your compressed air dryer. Not doing so could affect your compressed air dryer performance and lead to a catastrophic failure downstream. Every 30-60 days you should…

Is your fuel gas fired engine struggling to burn a wet fuel gas supply?

Is your fuel gas fired engine struggling to burn a wet fuel gas supply? PROBLEM: It is very common to hear customers complain about their gas fired engines struggling to burn a wet fuel gas supply. Although this problem occurs more frequently in the winter months where the…