Do I really need an aftercooler on the Blast Pak Pro Compressed Air Dryer System?

Recently one of our distributors that sells and rents portable air compressors asked me this question. The newer portable air compressors have an integral air-cooled after cooler on board so they thought the after cooler on the Blast Pak was redundant. I explained to them that “approach temperature” means everything when talking about after coolers. The lower the approach temperature the after cooler achieves the better, kind of like a golf score, lower is better. The after cooler on the Blast Pak is a close approach cooler, meaning the discharge temperature from the after cooler will be within 8-10F of the ambient temperature. Typically, after coolers that are integral to air compressors only achieve a 20-25F approach temperature.

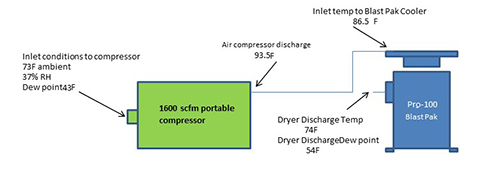

To prove to them the value of the after cooler on the Blast Pak PRO we conducted a test at their facility. We used a 1600 scfm portable air compressor with integral air cooled after cooler and connected it via 25 ft. of flex hose to the Blast Pak PRO-100. Below is a detailed analysis of the test we conducted. If you aren’t one for reading facts, figures, and formulas skip to the bottom of this blog for the summation.

SYSTEM ANALYSIS BASED ON ABOVE CONDITIONS

If the compressor is operating at 100 psig discharge pressure, then the dew point of the air after compression is as follows:

: 43F dew point = 3.195 gr/scf x 114.7/14.7 = 24.92gr/scf; this equates to a 108F outlet pressure dew point from the air compressor This means as long as the ambient temperature is below 108F water will condense out in the system. Since our ambient temp on this day was 73F we are definitely condensing out water. The after cooler on the portable compressor is producing ~20F approach to ambient to give us a 93.5F Discharge temperature. The compressed air is still saturated at this point and will continue to condense out water as the compressed air inside the hose tries to reach equilibrium with the 73F ambient condition. We picked up an additional 7 degrees of cooling in the 25’ hose run and 8 degrees of cooling with the after cooler on the Blast Pak. The working temperature inside the dryer is 74F and the Dry-O-Lite desiccant will suppress the dew point by 20F.

Therefore, our outlet dew point from the Blast Pak is 54F based on the conditions of the day. Keep in mind the temperature of the compressed air is 74F but the dew point is 54F. Since our ambient temperature is 73F and our dew point is 54F we will no longer condense any water downstream of the dryer because our outlet dew point from the Blast Pak is 19F below ambient temperature.

The system is self-compensating based on ambient temperatures and will always suppress the dew point 20F below the entering compressed air temperature to the Dryer on the Blast Pak.

SUMMATION: The answer to the initial question is “YES”, you do need the after cooler the Blast Pak PRO. In the test we conducted above the after cooler on the PRO-100 provided us with an additional 8 degrees of cooling. This translates to huge savings when it comes to desiccant consumption/operating cost. Without the after cooler on the Blast Pak PRO the customer will consume 3095 lbs of Dry-O-Lite desiccant/2000 HRS. With the after cooler the consumption drops to 2070 lbs of Dry-O-Lite desiccant/2000 HRS. This translates to operating cost savings of $1200.00/2000 HRS.