Air Receiver Tank Sizing & Additional Info

When it comes to air receiver tank sizing, an exact answer really depends on the specifics of the application. But a good rule of thumb is that a tank should be 1-3 gallons per SCFM of air system capacity. For example, if you have a 500 SCFM compressed air system you will likely need a receiver tank that’s between 500 and 1500 gallons.

I recently visited a large steel mill whose compressed air system is enormous, with a capacity to deliver about 40,000 SCFM. The air is dried and filtered to a pressure dew point of -40. I met with a plant engineer who was having a problem in one area of the mill. The steel producer had recently completed a major renovation and installed some new equipment that is controlled by twenty pneumatic actuators. These actuators are critical. Yet prior to my visit, liquid water had damaged some of the valves. At first this was a mystery, since the plant has well functioning centralized compressed air drying. We soon figured out that the damage occurred because backup portable compressors had been brought in during an outage of one of the central centrifugal air compressors. The back-up compressed air was not being dried.

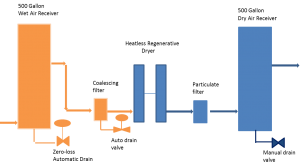

We calculated that this part of the mill required 500 SCFM of compressed air. So I recommended they install a 500 gallon “wet air” receiver tank with a zero-loss drain valve, coalescing filter for oil removal, a heatless regenerative dryer, a particulate after-filter, and a 500 gallon “dry air” receiver. The “wet air” receiver will catch those slugs of water they see when the portable compressors are hooked into the system, and the “dry air” receiver will buffer the dryer when the large pneumatic actuators cause demand spikes in excess of the compressor’s and dryer’s capacity.

Here is the proposed layout schematic for the steel mill:

Van Air Systems does not manufacture receiver tanks, but occasionally our customers will ask us to help incorporate a receiver into total system air treatment package . There are several large manufacturers of tanks that we refer our customers to for these instances.

What is an Air Receiver Tank?

A receiver tank, also called an air storage tank, is an economical system addition that enhances the performance of other components in your compressed air system, and gives you additional compressed air capacity for times when demand surges. A properly sized receiver can buffer the load on your air compressor and keep the compressor from short cycling. In short, a receiver tank saves energy.

Wet vs. Dry Air Receiver Tanks

We in the compressed air industry refer to receiver tanks as either “wet air” receiver tanks or “dry air” receiver tanks. Both of these tanks will store compressed air and add capacity to your system.

Wet Air Receiver

A “wet air” receiver is installed upstream of the filters & dryer. In addition to storing compressed air a “wet air” receiver tank will also protect your filters and dryer from slugs of water that will occur if an upstream separator or drain fails.

Dry Air Receiver

A “dry air” receiver tank allows demand to be pulled from the tank rather than subjecting the dryer to instantaneous surges. These surges can push the dryer beyond its rated capacity and affect dew point performance and pressure drop.