Choosing Replacement Desiccant: Pitfalls to Avoid

Desiccant doesn’t last forever, regardless of the type of compressed air dryer that you have. All desiccant needs to be replaced or replenished eventually. However, a few things have to be pinned down before deciding what material is most appropriate for the dryer.

What Type of Dryer is it?

Most importantly, what type of dryer is it? An odd thing I’ve noticed is that many customers can’t readily answer this question, although they know it needs desiccant. Often it’s no use asking a customer to consult the dryer’s manual. Those things always get lost. There must be a federal law stating that dryer instruction manuals cannot be in the same state as the actual dryer. (Did you know that a lot of Van Air Systems manuals are posted on the product pages of the website?)

Not knowing what type of dryer you’ve got but requesting replacement desiccant is much like going into an auto parts store and saying that you need some fluid and leaving it at that. We all know what the counter person will do. He or she will ask, What type of vehicle is, what's the model, and what type of fluid is needed? Knowing the type of dryer is just as critical. This keeps customers from knowing which desiccant to buy and importantly, buying the wrong type of desiccant. Picking the wrong desiccant always leads to an unhappy ending.

The worst scenario is where an absorbent deliquescent desiccant is put into a regenerative dryer. This occurs (thankfully, not often) when a buyer sees the word “desiccant” but ignores the word “deliquescent” and figures that this new stuff is cheaper than the activated alumina desiccant he’s previously purchased. The buyer gets a gold star for saving money, while the plant engineer has a severely damaged dryer at best.

Occasionally I get a call from someone filling a dryer, complaining that these big fat desiccant tablets (a.k.a Dry-O-Lite) are hard to get into the vessel, not like the little desiccant balls (a.k.a. activated alumina) used before. I tell the person to stop immediately. At this point, no harm’s been done. But if he’d gone much further and continued to fill his regenerative dryer with deliquescent, the wheels really would have come off. He’d have called with a complaint about valves filling with liquid, no dew point performance, high pressure drop or a failure to switch. If the deliquescent solution gets into the control air lines, it may be a total rebuild of the control system and valves.

Going in the other direction, you can also put adsorbent desiccant (e.g. activated alumina, silica gel, molecular sieve dryer) into a single tower dryer. But with no regeneration system, the desiccant doesn’t work for long. There is great dew point depression for a few hours followed by nothing. Although there may be water downstream, in the case of this desiccant selection error, there will be no damage to the dryer itself. But the end-user will have to suck out the desiccant with a shop vacuum.

How to Select the Right Desiccant?

So, whether you’re an end-user looking for the right drying media or a customer service rep at an equipment distributorship who's looking to help a customer, how do you select the right desiccant? Here are some key questions to answer about the dryer:

How many towers does the dryer have? If there are two towers, you need an adsorbent. If there’s just one tower, you most likely need an absorbent deliquescent.

Is there a model number/serial number on the pressure vessels or inside the control box? Note: if there's a control box, it's not a single tower deliquescent dryer.

Do you know what material you bought the last time?

What size is the material in there now? If you don’t know but are sure it’s an adsorbent, use ¼” activated alumina. This will guarantee that the beads won’t fall through the dryer’s screen. Or you can send me a sample of beads, and I’ll figure out what material best matches up. Note that all of the standard Van Air Systems regenerative dryers use 1/8” (2-5 mm) activated alumina.

How much do you need? If the amount is unknown, get the tower dimensions, and I’ll help you figure it out.

When do You Need to Replace?

Another important question is, “when do I replace it?”

Single tower deliquescent dryers. Trick question! You don’t replace the deliquescent desiccant. You replenish it by just adding more. Check the sight windows on the dryer vessel. When you can’t see any desiccant, fill the vessel up to the weld seam. (Remember the trick to the successful operation of a deliquescent dryer: D2F2 = Drain Daily and Fill Full).

Twin tower regenerative desiccant dryers. The textbook practice is every 3-5 years. But just as often, the rule for replacing adsorbent desiccant is, When the old stuff no longer works. Of course, the word works is open to a lot of interpretation based on a customer’s tolerance for moisture in the air system. It ranges from-

The dryer is operating properly but is not producing the specified dew point. You need a good dew point meter to determine whether this is the case.

There is water downstream. The quickest way to confirm this is by cracking the ball valve on the particulate after-filter. If any liquid whatsoever comes out, it's time to replace the desiccant.

Questions?

If you still have any doubts, call me. Let me repeat that. If you need any help picking the right desiccant, pick up the phone and dial 800-840-9906. Or get in touch with Van Air Systems by email, info@vanairsystems.com.

If you have a sample that you want us to inspect or test for moisture retention, please call before dropping it in the mail. The service is free, but we need to assign you a case number. Otherwise, your desiccant sample might arrive here and end up working as a door stop in our office.

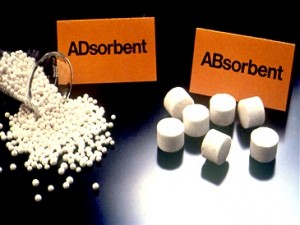

Finally, here’s a photo that shows a picture of two different classes of desiccant we offer. On the left, you see activated alumina, an adsorbent. This is the stuff that goes in regenerative desiccant dryers (two towers, control box, purge air, solenoids, etc.) On the right, you see Dry-O-Lite tablets, which are absorbent. This stuff goes in single tower deliquescent dryers (one vessel, drain valve at the base).