Simple Maintenance Steps to Keep your Compressed Air System Running Well.

Simple Maintenance Steps to Keep your Compressed Air System Running Well.

Beat the Summer Heat and Humidity with a simple walk-through of your Compressed Air System - saving you from unwanted downtime.

1. Start by checking your air compressor:

First check the suction filters for any tears, bypassed seals, excessive dirt and back pressure. Change or clean these filters as required. Next check that the compressor is properly cooled and there are no blockages or excessive dirt on heat transfer surfaces. If the compressor is water cooled, make sure the heat exchanger is clean and there are no restrictions in water flow. Verify your cooling water cleanliness, pressure and temperature. Check oil levels and service with an oil change or by adding oil if required. If the compressor’s load hours to service intervals indicate too much idling, consider adjusting the sequencing controls per the manufacturer's recommendations.

Once the compressor system is fully serviced and verified to be operating at the proper temperature and pressure, it is time to check the treatment and distribution systems.

2. Check other all air lines, piping and fittings for leaks.

3. Inspect your drains.

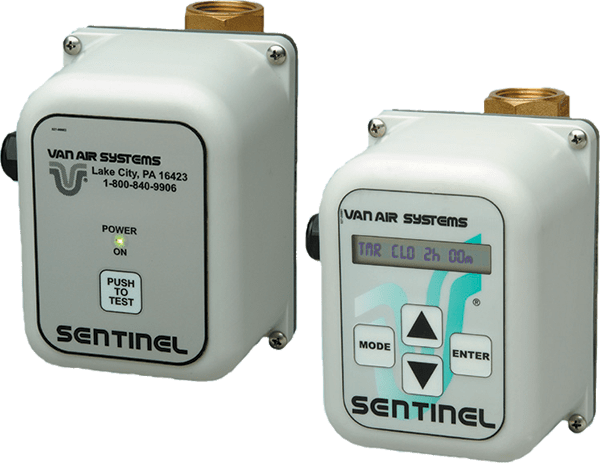

Inspect drains on separators, drop legs, and dryers. Pay special attention to any drain on the receiver tank between the compressor and the dryer. This is called the wet receiver, and it will see the highest volume of condensate. If you’re depending on manual drains to remove condensate, switch to automated drains.

Note that a little bit of compressor lubricant is normal in the condensate being drained from the wet receiver, separator, and coalescing filter. But if there is a substantial amount of oil, there’s likely a problem with the compressor. Consult your compressor supplier for assistance fixing the problem.

4. Service the Air Treatment Equipment – Compressed Air Dryer and Compressed Air Filters

Checking the Compressed Air Filters:

Checking the Compressed Air Filters:

It is important to replace filter elements. We recommend replacing your compressed air filter elements every six months. However it is important to do service checks periodically. Some common reg flags are as follows: If a coalescing filter is flooded it can indicate a failed automatic drain either at the filter or upstream. Check the pressure differential across filters when flowing near or at capacity. If the differential is more than 5 PSID across a filter, it’s time to replace the elements. Watch out for zero pressure differential, as you might have a torn or ruptured filter element. Replace as necessary.

Checking the Compressed Air Dryer:

Desiccant Air Dryers: If you have a single tower desiccant air dryer checking the desiccant level during these hot and humid summer months is crucial. You can check to see if you need to add desiccant tablets by looking at the sight window located on your Compressed Air Dryer. If you don’t see tablets, refill as necessary. When replacing desiccant in your dryer, safely isolate and depressurize the vessel before opening the filler hatch. Also replace the hatch gasket during every service interval.

Desiccant Air Dryers: If you have a single tower desiccant air dryer checking the desiccant level during these hot and humid summer months is crucial. You can check to see if you need to add desiccant tablets by looking at the sight window located on your Compressed Air Dryer. If you don’t see tablets, refill as necessary. When replacing desiccant in your dryer, safely isolate and depressurize the vessel before opening the filler hatch. Also replace the hatch gasket during every service interval.

Refrigerated Air Dryers: If you have a refrigerated compressed air dryer, check that the condenser is clean. Never situate the dryer against a wall where air flow across a condenser is restricted. Check for pressure drop across the evaporator. If it is high you will need to verify capacity and cleanliness. Check that the evaporator temperature is within specification. If not you will need to have the system serviced by a qualified refrigeration service technician.

Dual Tower Regenerative Air Dryers: Check the outlet moisture content. Many dryers include a color changing indicator, where blue means  dry and pink means wet. If you find the color change indicator is pink, verify the dryer is switching properly, that the purge setting is correct, and that there is no oil or liquid water present at the purge exhaust. If the purge exhaust mufflers are oily to the touch, you’ve likely got a problem. If you suspect oil contamination of a desiccant bed, block the dryer in, verify it is fully depressurized, and obtain several desiccant samples from as deep in the bed as possible. If the desiccant is tan or brown, it needs replacing.

dry and pink means wet. If you find the color change indicator is pink, verify the dryer is switching properly, that the purge setting is correct, and that there is no oil or liquid water present at the purge exhaust. If the purge exhaust mufflers are oily to the touch, you’ve likely got a problem. If you suspect oil contamination of a desiccant bed, block the dryer in, verify it is fully depressurized, and obtain several desiccant samples from as deep in the bed as possible. If the desiccant is tan or brown, it needs replacing.

It is important to always verify that your dryer is operating within its design conditions with respect to temperature, pressure and flow capacity. Most dryers are designed for 100⁰F inlet compressed air. Performance of the dryer will degrade as the inlet temperature rises. Once you have checked everything on the dryer and its still not performing as it should, contact the manufacturer for support.

Checking on these components of your air system are crucial to keep it running smoothly. A little walk-through of your system can save you from unexpected downtime. You can also be one step ahead by having spare parts such as filter elements, desiccant and drain valves on hand for the next time you do a system walk-through.

If you are experiencing any issues with your air system, we can always be of support. For questions about your system, or to purchase replacement parts, please contact us at info@vanairsystems.com or 1-800-840-9906.