Install a Deliquescent Dryer (with 10BF desiccant) after a Refrigerated Dryer to Lower Dew Point

Here’s an interesting question I am occasionally asked: If I install a deliquescent dryer after a refrigerated dryer will I get a lower dew point?

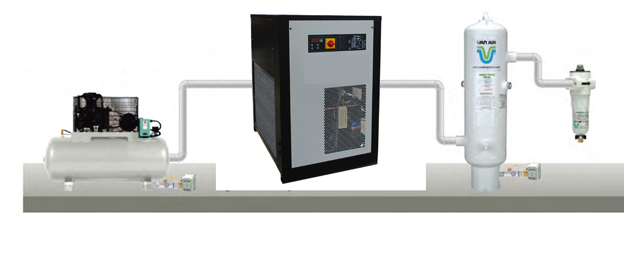

Here’s what such an installation would look like:

A refrigerated dryer delivers a dew point of 38°F to 50°F. But often a compressed air user needs a lower dew point to protect air lines from freezing. Yet he doesn’t want the high operating expense of a regenerative desiccant dryer.

So can a deliquescent dryer be used to “polish dry” the air from a refrigerated dryer?

The answer is yes! But you have to pick the right type of deliquescent desiccant. Let’s dig into some details.

In a typical application compressed air exits a refrigerated dryer with a temperature of 78°F to 85°F and a dew point of 38°F to 45°F. In other words, the refrigerated dryer has suppressed dew point of the compressed air by around 40°F.

Our standard and most popular deliquescent desiccant – Dry-O-Lite – suppress dew point by not more than 20°F. That suppression factor is applied to the temperature of the air. So Dry-O-Lite can lower the dew point of 78°F compressed air to as low as 58°F. Yet because in this application the refrigerated dryer has already lowered the dew point to around 40°F, Dry-O-Lite desiccant has no additional drying effect.

But consider the same application using 10BF, our highest performing deliquescent desiccant. It’s three times more potent than Dry-O-Lite (and also costs more). 10BF suppresses dew point by about 60°F. Again, this suppression factor is applied to the temperature of the compressed air. So compressed air with a temperature of 78°F being treated with 10BF will have a final dew point of about 18 °F (78 °F - 60°F). That’s lower than any refrigerated dryer could achieve. So in this case installing a deliquescent dryer filled with 10BF after a refrigerated dryer substantially improves (lowers) the dew point in the air system.

That’s good news for operators wanting to prevent freeze ups in an air system.

But 10BF is expensive. Won’t operating cost for the 10BF be too high? Again, there’s good news to report. Thanks to the refrigerated dryer, most of the water has been removed from the system, lessening the load on the deliquescent dryer. A 100 CFM system running at typical pressure and temperature conditions will only use about 5 lbs of 10BF per month, assuming continuous flow 40 hours per week.

The added protection will be worth it.