Should You Use a Refrigerated Dryer with a Desiccant Dryer?

Can a heatless dryer be undersized if a refrigerated dryer is located immediately upstream? This is a recurring question from both end-users and equipment distributors. Upon first consideration it seems reasonable. The refrigerated dryer will considerably reduce the moisture load on the heatless desiccant dryer. So it should be ok then to downsize the heatless dryer, right?

Wrong.

Here are two reasons why the idea falls apart.

One, heatless desiccant compressed air dryers typically use activated alumina desiccant. Activated alumina exhibits a decreasing adsorption capacity at low relative humidity (RH) and a refrigerated dryer, by cooling and reheating compressed air, lowers the RH of compressed air. In other words, the refrigerated dryer actually undermines the ability of the desiccant media to adsorb moisture to its surface.

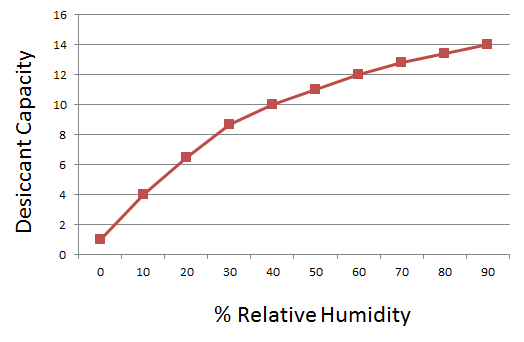

The chart below shows how the adsorption capacity of activated alumina decreases with declining RH for a typical fixed pressure and temperature. The y-axis shows the adsorption capacity percentage of water load to activated alumina by weight.

A 100 SCFM flow of compressed air saturated at 100°F (100% RH) and 100 psig has 0.2 lbs. water per 5 min adsorption cycle. (A five minute adsorption cycle is typical in a heatless dryer.) The application requires 62 lbs. of activated alumina desiccant to dry the air to a -40°F pressure dew point.

The same 100 SCFM flow of compressed air leaving a refrigerated dryer at 85°F and 95 psig with a 38 °F pressure dew point (19% RH) has only 0.026 lb water per 5 min adsorption cycle. Yet drying this stream of air requires 60 lbs. of activated alumina desiccant to dry the air to a -40°F pressure dew point. While there is an 87% reduction in water load at the heatless dryer inlet, the size of the heatless dryer has been virtually unaffected. Now consider the operating cost of the additional pressure drop through the refrigerated dryer and the extra capital cost of operating two dryers. It just doesn’t make a lot of sense.