Abrasive Blasting & Coatings Search Results for: “”

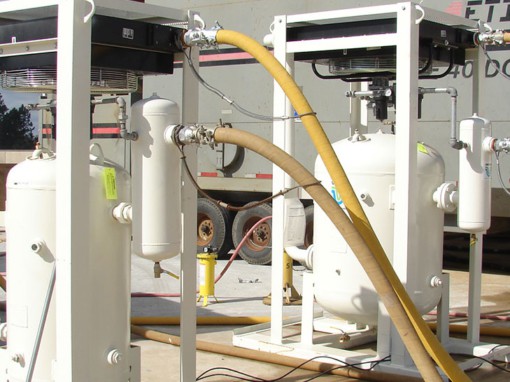

Compressed Air Dryers For Blast Pots & Nozzles

Moisture in compressed air negatively affects both the productivity and workmanship of abrasive blasting contractors. The harmful effects of wet air include the clumping or clogging of abrasive grit, inconsistent and/or excessive flow of abrasive, corrosion of ferrous abrasives, and damage to blast machine valves and controls. When abrasive media…

Stationary Compressed Air Dryers For Mobile & Stationary Paint Booths

Water in compressed air lines causes paint and coatings to drip, bubble, and “fish-eye”. Wet compressed air may also dilute the paint, both increasing the cure time and affecting the adhesion of the coating to the steel surface. Properly cooling, drying, and filtering compressed air eliminates re-work and increases the…

All-In-One Compressed Air Treatments For Flash Rust Prevention

Abrasive blasting exposes a steel substrate to atmospheric humidity, and blasting contractors must contend with “flash rusting”. Flash rusting is surface corrosion that appears on steel when it’s not coated quickly enough. The presence of liquid water in compressed air exacerbates a contractor’s problems with flash rusting. Liquid water in…

Deliquescent Compressed Air Dryers for Blast Cabinets & Booths

Abrasive blast cabinets and booths are used to clean metal parts in a variety of industrial settings. Compressed air propels an abrasive media against the metal part, removing old paint, corrosion, scale, and other build up. Certain abrasives types are highly sensitive to moisture in the compressed air, especially steel…